Attendance

- Hunter

- Mark

- Evan

- Fletcher

Journal

Tasks

- Figure out how to make the servos work

- Improve the notebook

- Make last adjustments to robot

- Test everything and troubleshoot problems

- Make the posterboard for the display

Reflections

Today we had a build day at Evan’s house.

First thing we worked on was the servos. Hunter tried changing the serial order that controller boxes were in to no avail. We then tried just plugging in the servo box with no motor controllers, still with no avail.

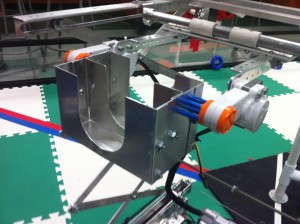

Fletcher came in late due to a Horn section function and looked at the code. After several more non-successful attempts, Fletcher revealed that he and Mr. Corey Porter, a computer engineer at a company, edited the servo part of our TeleOp. Fletcher applied the edit to our present TeleOp and then tested it on the robot with promising results! The hand twitched when we pressed a button and twitched in a different direction when we pressed a different button. Another button made the 360 servo turn, though it never stopped turning. After several tests where we commented out the commands that made the 360 servo go left and right, we decided that the 360 servo was demented. After closer inspection, Hunter found that the servo we were referring to as the 360 servo in the code was actually the plain servo. After this problem resolved, the hand opened and closed beautifully. After uncommenting all the 360 servo commands, it also worked beautifully.

After we got our servos working, we made sure all the other bits on the robot worked. The NXT motors that rotate rings gave us a little trouble, but after several tests, we got it working.

After we got all of our technical difficulties sorted, we turned our attention to the user interface for the driver. Hunter made two buttons, B and Z, that tuned the levelness of the scissor lift. We moved general scissor lift control from the right side to the left side of the controller for ease of tuning.

The robot is now functional and is ready for our first competition tomorrow at the Coachella Valley.