Attendance

- Mark

- Evan

- Hunter

- Chris

- Dante

- Erik

- Fletcher

Journal

Tasks

- Install elastic bands

- Install new encoders

- Test TeleOp

- Get permission slip forms out to whole team

- Test and fix the scissor lift

Reflections

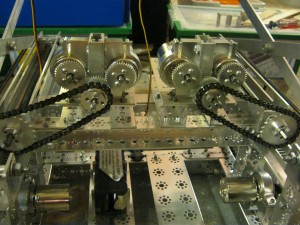

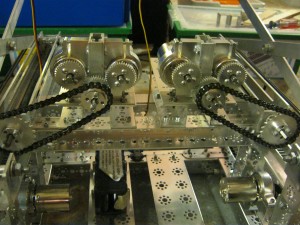

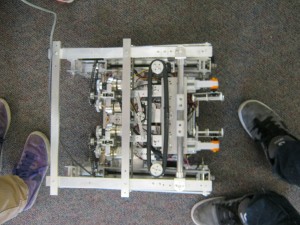

Today we put the finishing touches on our robot. We put our last encoders on two of the motors that power the scissor lift to make the autonomous more accurate. We twisted the elastic bands together to further increase the tension on the lift. We started to test the autonomous and had to make quite a few changes to it because it didn’t really work at first. we also tested the TeleOp a little and had to make changes to that as well.

We discussed a lot about the competition on Saturday at Cochilla valley about things such as who the drivers and coach will be which we will finalize after more testing on Thursday, we finalized our spreadsheet of questions to ask all of the other groups.

Mr. Dobson confirmed that we would all go on Thursday to Bradoaks, one of the elementary schools, to bring our robot and talk to the GATE (honors) program about robotics to try to get them interested in it so they might join robotics in middle or high school. A lot of testing took place today as well as a lot of changes to the programming because there were many problems.

We found that the servos on the robots are crazy; especially with coding it. Most of the day was spent attempting to code the servo with no success.

After Evan attached the encoders to the scissor motors, Fletcher wrote a test autonomous that told the robot to rotate the scissor motors 400 units and it succeeded! Hooray!